Battery pioneer Britishvolt will anchor its UK battery scale up facilities in the West Midlands, with an investment exceeding £200 million, with partner Prologis that will create and sustain upwards of 150 highly skilled and well-paid technology jobs. Leasing the facility enables Britishvolt to rapidly ramp up cells that are production ready to be manufactured in larger volumes at its Northumberland Gigaplant.

Paul Franklin, Property Director, Britishvolt:

“This is another important milestone for Britishvolt, UK plc and its world class automotive industry. The UK’s battery ecosystem is a global leader in integrated technology development and industrialisation with the Warwick Manufacturing Group, Faraday Institution, UK Battery Industrialisation Centre and the Advanced Propulsion Centre. I am delighted to see Britishvolt lead the UK’s journey into re-industrialisation with the first full-scale battery Gigaplant. The new R&D and scale-up facilities announced today will help the UK build on its home-grown battery intellectual property and level up the country ready for the energy transition.”

To summarise the importance of the facility:

- Hams Hall is destined to become a centre of excellence for all things EV/Electrification, with major automakers close by.

- The facility will complement the Britishvolt value proposition for customers at Cambois, Northumberland and support the smooth startup of Gigaplant operations in 2024.

- Practical completion of the development is anticipated in July with fit out and equipment installation to be undertaken through to end Q3, 2023.

Tom Price, Capital Leasing & Deployment Director, Prologis UK:

“Partnering with innovative technology brand Britishvolt has been a pleasure. The reputation of Hams Hall and the location’s connections to the UK automotive sector has allowed us to embark on a wider conversation with Britishvolt. With battery technology seen as the way forward, it’s exciting to be working in this growing sector.

“Prologis is committed to embedding sustainability into every aspect of our business. When looking at “last-mile” logistics, that is the final delivery of goods to people’s homes, it’s clear that the work Britishvolt are embarking on will contribute to reducing emissions in supply chains”

The West Midlands is already a “golden triangle” of international battery excellence with the Warwick Manufacturing Group, Advanced Propulsion Centre and UK Battery Industrialisation Centre. This new investment and commitment to the region will further unlock the huge economic potential of the UK’s world-class battery cell ecosystem.

Andy Street, the Mayor of the West Midlands:

“Britishvolt’s investment in the West Midlands is another seismic vote of confidence both in the future of our region and our automotive prowess. We are already the heartland of the UK’s automotive industry with the country’s biggest car manufacturer, Europe’s largest research centre of its kind, the UK’s only battery industrialisation centre, and a world-leading supply chain. So, it is incredibly exciting that as we accelerate our Gigafactory plans for Coventry Airport, Britishvolt are adding their expertise to our cluster.

“I am determined the West Midlands becomes a global leader in the research and production of state-of-the-art battery technology, and today’s announcement is another step towards achieving that.”

Charles Spicer, Industrial and Logistics Director at Savills Birmingham, comments:

“This is a hugely exciting emerging sector that Savills has been tracking for number of years. We are delighted to have acquired this new site for Britishvolt at the heart of the UK’s automotive industry, which is a major endorsement for the wider West Midlands industrial market.”

Britishvolt has already developed pre-A battery samples at WMG in Warwick and is scaling up its unique A-Sample cell formulations at UK Battery Industrialisation Centre in Coventry. This new £200 million investment, coupled to the unique regional battery expertise, enables Britishvolt to develop new formats and formulations helping to make both higher performance and more affordable cells for the world’s future electric cars & commercial vehicles.

Britishvolt’s collaborations with academia, industry and private enterprise will also help transition the UK from fossil fuels to a low carbon, battery-based electric future.

Britishvolt has already confirmed MoUs with Lotus Cars and Aston Martin Lagonda, which, alongside other commitments to be announced shortly, have cumulative demand in excess of 7GWh in 2024 and 2025, and set the stage for the full 38GWh factory capacity that will be supplied annually from its Gigaplant site in Northumberland.

The release of an official A-sample battery cell to customers, which is scheduled in 2022, will help to further accelerate commitments.

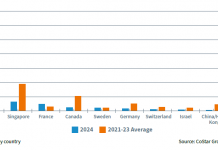

Britishvolt is one of the fastest growing battery technology companies in Europe and globally. The company is also in discussions with the Canadian Government regarding its expansion plans in the country.